Which fan is commonly used in a warehouse?

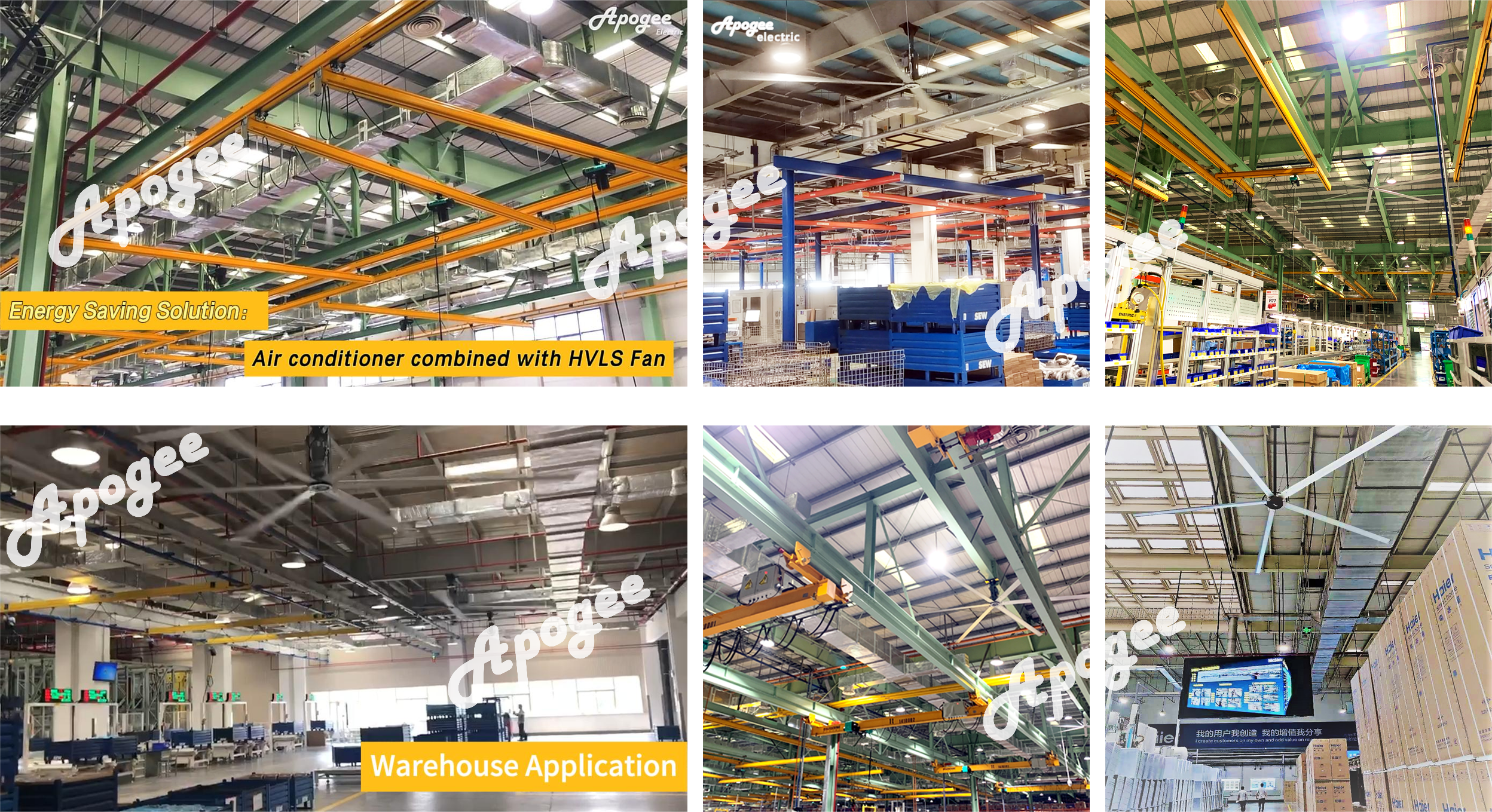

In the logistics and manufacturing warehouse sectors, efficient air management is not merely about worker comfort—it directly impacts operational costs, equipment longevity, and inventory integrity. High Volume, Low Speed (HVLS) fans have emerged as the industry standard for warehouses. HVLS Fans have emerged as the gold standard for large-scale warehouses due to their innovative design and multifaceted benefits.

HVLS Fans

•Purpose: Designed for large spaces, these fans move massive volumes of air at low rotational speeds.

•Features:

*Blade diameters up to 24 feet.

*Energy-efficient, gentle airflow for uniform temperature and humidity control.

*Ideal for high ceilings (18+ feet).

•Benefits: Reduces energy costs, prevents stagnant air, and improves worker comfort without disruptive drafts.

1. Massive Air Movement with Minimal Energy

•Physics of Efficiency: HVLS fans have enormous blades (10–24 feet in diameter) that rotate slowly (60–110 RPM). This design moves a high volume of air downward in a wide column, creating a horizontal floor jet that spreads across the entire space.

•Energy Savings: A single HVLS fan can replace 10–20 traditional high-speed fans, reducing energy consumption by up to 30–50% compared to conventional cooling systems.

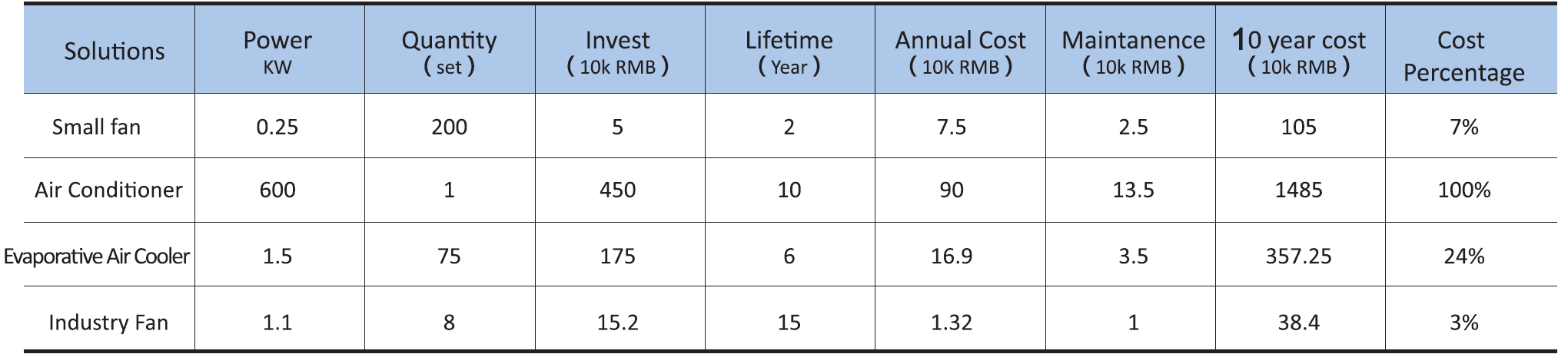

Comparison among HVLS Fan (industry fan), small fans, air conditioner, evaporative air cooler:

2. Aerodynamic Efficiency for Large Spaces

Warehouses often exceed 30,000 sq. ft. (2,787 m²) with ceiling heights over 30 feet (9 meters). Traditional fans struggle in such environments due to:

• Air Stratification: Warm air rises, creating temperature layers (up to 15°F/8°C difference between floor and ceiling).

• Short-Throw Limitation: High-speed fans only cool immediate areas (<50 ft/15 m coverage).

HVLS fans overcome these issues through:

• Vertical Air Column: Blades push air downward in a cylindrical column spanning the fan’s diameter.

• Horizontal Floor Jet: Upon reaching the ground, airflow spreads horizontally via the Coanda Effect, covering radii up to 100 ft (30 m).

• Destratification: Mixes air layers, reducing vertical temperature gradients to <3°F (1.7°C).

3. Uniform Climate Control

• Eliminates Stagnant Air: Warehouses often suffer from "stratification," where hot air rises to the ceiling and cool air sinks. HVLS fans break this cycle by mixing air layers, maintaining consistent temperatures and humidity levels.

• Seasonal Flexibility:

*Summer: Creates a wind-chill effect, cooling workers by 5–10°F without drafts.

*Winter: Recirculates warm air trapped at the ceiling, cutting heating costs by 20–30%.

4. Worker Comfort and Safety

The Occupational Safety and Health Administration (OSHA) identifies poor ventilation as a key contributor to workplace injuries. HVLS fans provide below comfortable experience:

• Gentle, Draft-Free Airflow: Unlike high-speed fans, HVLS fans produce a steady breeze that avoids disruptive gusts, reducing fatigue and heat stress.

• Moisture/Dust Control: Prevents condensation (critical in cold storage) and disperses airborne particles, improving air quality and safety.

• Slip Hazard Mitigation: Cuts condensation by 80% in cold storage (e.g., Lineage Logistics reported 90% fewer wet-floor accidents).

5. Cost-Effective for Large Spaces

• Coverage: One 24-feet fan can efficiently cover up to 1,5000 sq. ft., reducing the number of units needed.

• Low Maintenance: Durable, industrial-grade construction with fewer moving parts ensures longevity and minimal upkeep.

Key Warehouse-Specific Advantages:

Why Not Smaller Fans?

Smaller high-speed fans create localized, turbulent airflow that doesn’t penetrate large spaces effectively. They also consume more energy per square foot and generate noise. HVLS fans solve these issues by leveraging aerodynamics (like the Coanda effect) to spread air smoothly across vast areas.

HVLS fans have revolutionized warehouse climate control through unmatched efficiency, safety enhancements, and cost-effectiveness. By moving air smarter – not harder – these systems address the unique scale challenges of modern logistics spaces while supporting sustainability goals. As warehouses grow taller and smarter, HVLS technology remains the backbone of industrial ventilation strategies, proving that sometimes, slower really is better.

Post time: May-22-2025