A beautiful, well-installed fan is useless—and potentially a lethal hazard—if its safety systems are not engineered to the highest possible standard. Safety is the bedrock upon which good design and proper installation are built. It’s the feature that allows you to enjoy the benefits of the fan (comfort, energy savings) with complete peace of mind.

Safety Design (The Non-Negotiable Priority)

This is the most important layer, A failure in a fan of this size and mass can be catastrophic superior safety design includes:

● Redundancy in Critical Systems: Especially in the mounting hardware, Multiple, independent safety cables that can support the entire HVLS Fan‘s weight if the primary mount fails.

● Fail-Safe Mechanisms: Systems designed so that if a component fails, the fan defaults to a safe state (e.g., stops spinning) rather than a dangerous one.

● Material Quality: Using high-grade steels, alloys, and composites that resist metal fatigue, corrosion, and cracking over decades of use.

● Secure Blade Attachment: Blades must be firmly locked to the hub with systems that prevent them from loosening or detaching.

● Protective Guards: While often not full enclosures due to the size, critical areas like the motor and hub are protected.

Proper Installation (The Critical Link)

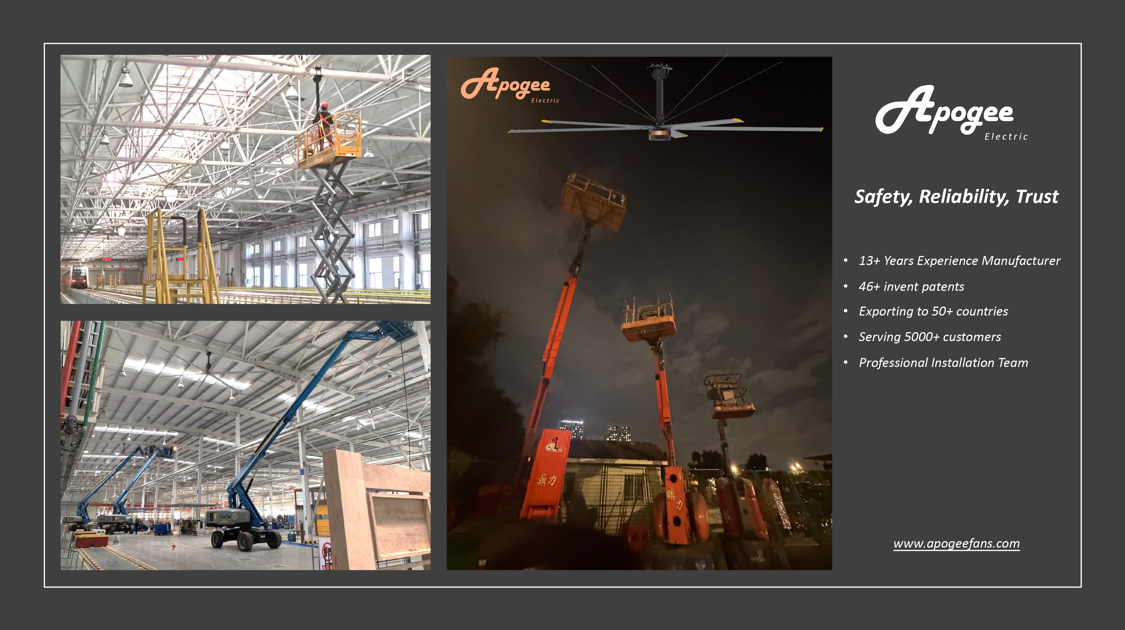

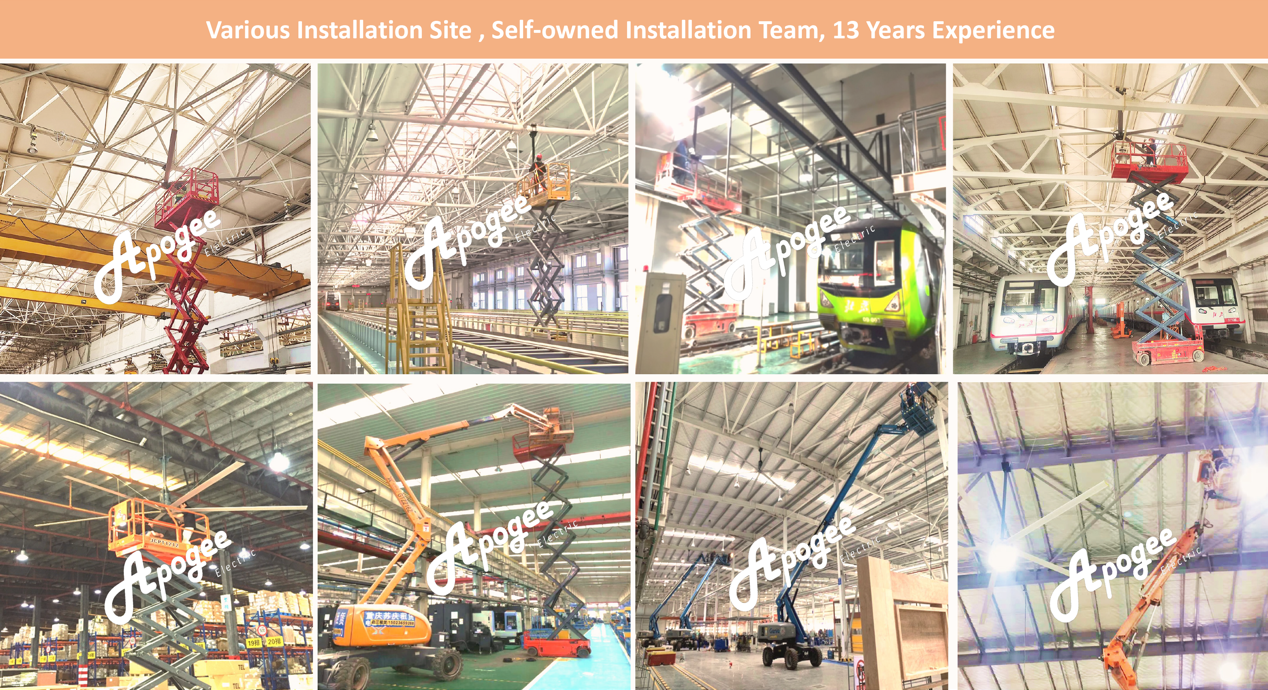

Even the best fan will underperform or be dangerous if installed incorrectly. We have accumulated 13+ years installation experience and have a professional technical team for supporting distributor installations.

Installation Requirements

Apogee will arrange professional installers to install according to the specific requirements and conditions of the customer. During the installation process, the installation project manager is responsible for implementing all-round management of the construction project and is responsible for the construction period, quality and safety. At the same time coordinate with the customer to ensure that the project meets the requirements. The installation project manager completes the safety operation procedures and the environmental protection system on site at the time of installation of the team.

Installation material preparation

Unpacking, check the packing list, check whether the fan materials are complete, check the physical and packing list one by one. If there is damage, missing parts, loss, etc., timely feedback, if the material loss is caused by logistics factors, relevant records should be made.

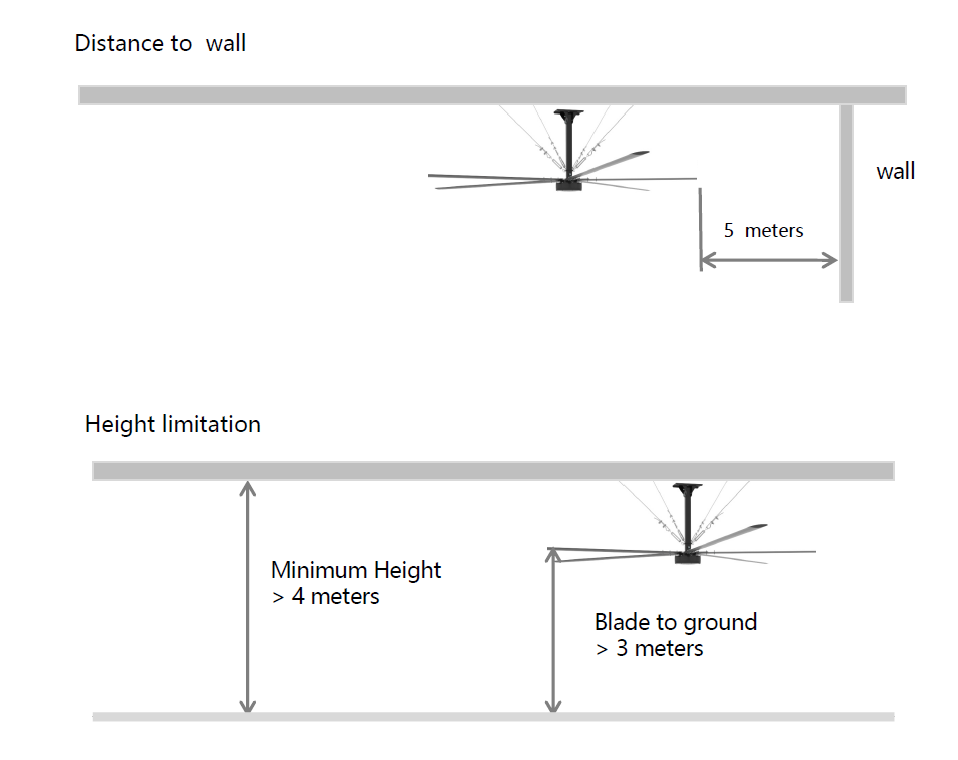

Safe Spacing

● Avoid installing the fan directly under the light or skylight to prevent ground shadows

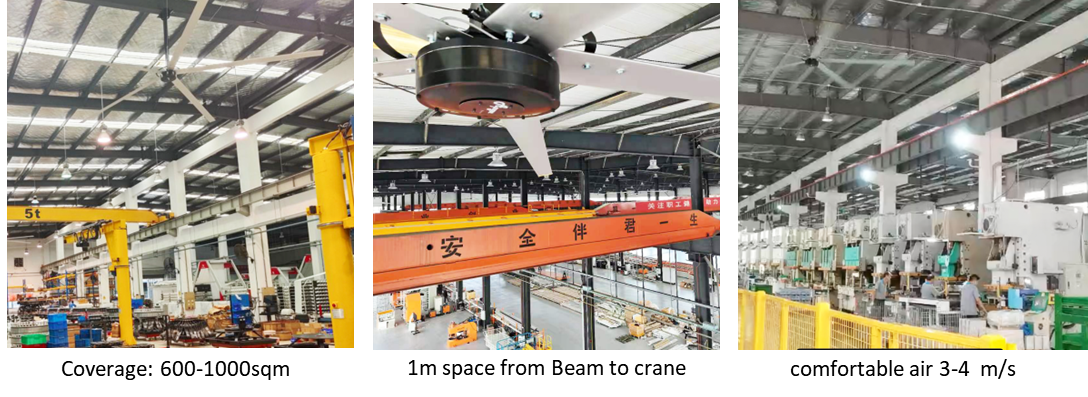

● The fan is best installed at 6 to 9 meters height, If the building is constructed and the internal space is limited (traveling crane, ventilation pipe, fire-fighting piping, other support structure), the fan blades can be installed at 3.0 to 15 meters height.

● Avoid installing the fan on the air outlet (air conditioning air outlet)

● The fan should not be placed in the area where the negative pressure is generated from the exhaust fan or other return air points. If there is an exhaust fan and a negative pressure return air point, the fan installation point should have 1.5 times the diameter of the fan.

Installation Procedure

Our safety and classical design is easy for installation, we have installation procedure documents and video, helping distributor easily handle the installation, we have various mounting base for each kind of construction, extension rod can fit various height up to 9m.

1.Install the installation base.

2.Install extension rod, motor.

3.Install wire rope, level adjustment.

4.Electrical connections

5.Install fan blades

6.Check run

The fan is a maintenance-free product with no wearing parts. Once installed, it can operate normally without daily maintenance. However, there are paid to whether there are the following abnormal conditions. In particular, if the fan is not used after a long period of use or the fan is stopped after long-term use, it needs to be checked. If there is any abnormality, stop using it and check it. For unexplained abnormal conditions, please contact the manufacturer for confirmation.

The fan needs to be regularly checked for safety at high altitude. The fan is used in a factory environment. The fan blades will accumulate more oil and dust, which will affect the appearance. In addition to daily inspection items, annual maintenance inspection is required. Inspection frequency: 1-5 years: check once a year. 5 years or more: Pre- and post-use inspection and annual inspection during peak period

If you want to be our distributor, please contact us through WhatsApp: +86 15895422983.

Post time: Aug-25-2025