Industrial fans and regular fans serve different purposes and are designed to meet specific needs. Understanding the differences between the two can help in making an informed decision when choosing the right fan for a particular application.

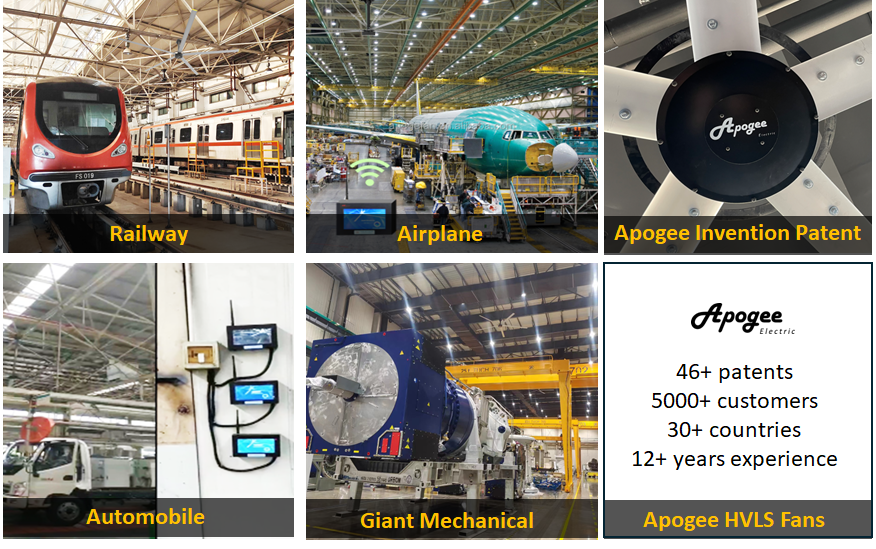

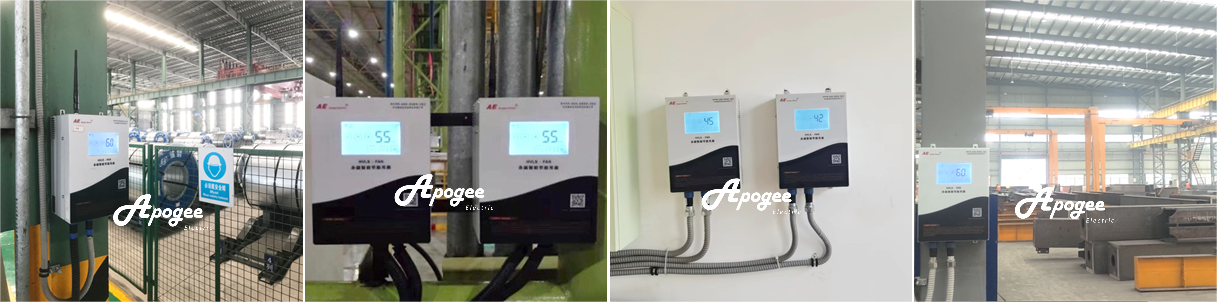

The primary difference between an industrial fan and a regular fan lies in their design, size, and intended use. Industrial fans, such as the Apogee industrial fan, are specifically engineered to provide high-velocity airflow and are built to withstand harsh industrial environments. They are typically larger in size and have a more robust construction compared to regular fans. Industrial fans are commonly used in factories, warehouses, workshops, and other industrial settings where there is a need for efficient air circulation, cooling, or ventilation.

Scale & Airflow Capacity:

• Industrial Fans: Move massive volumes of air (measured in thousands or tens of thousands of cubic feet per minute - CFM) over long distances or throughout large areas. They create significant air velocity even far from the fan.

• Regular Fans: Move modest volumes of air (typically hundreds to maybe a few thousand CFM) suitable for cooling people within a small radius (a few feet to maybe across a small room)

On the other hand, regular fans, which are commonly found in homes and offices, are designed for personal comfort and are generally smaller in size. They are not built to withstand the demands of industrial applications and are not as powerful or durable as industrial fans. Regular fans are often used for cooling small to medium-sized spaces and for creating a gentle breeze for personal comfort.

Size & Construction:

Noise Level:

In terms of performance, industrial fans are capable of moving a larger volume of air at higher velocities, making them suitable for large industrial spaces where air circulation and ventilation are critical. They are also designed to operate continuously for extended periods, providing consistent airflow and cooling. Regular fans, while effective for personal use, are not designed to handle the demands of industrial environments and may not provide the necessary airflow or durability required in such settings.

Additionally, industrial fans often come with features such as variable speed controls, corrosion-resistant materials, and heavy-duty motors, which are essential for withstanding the rigors of industrial operations. These features are not commonly found in regular fans, as they are not designed for the same level of performance and durability.

In conclusion, the main differences between industrial fans like the Apogee industrial fan and regular fans lie in their design, size, performance, and intended use. Industrial fans are engineered for industrial applications, offering high-velocity airflow, durability, and reliability, while regular fans are designed for personal comfort in smaller, non-industrial settings. Understanding these distinctions is crucial in selecting the right fan for specific needs and environments.

Post time: May-16-2024