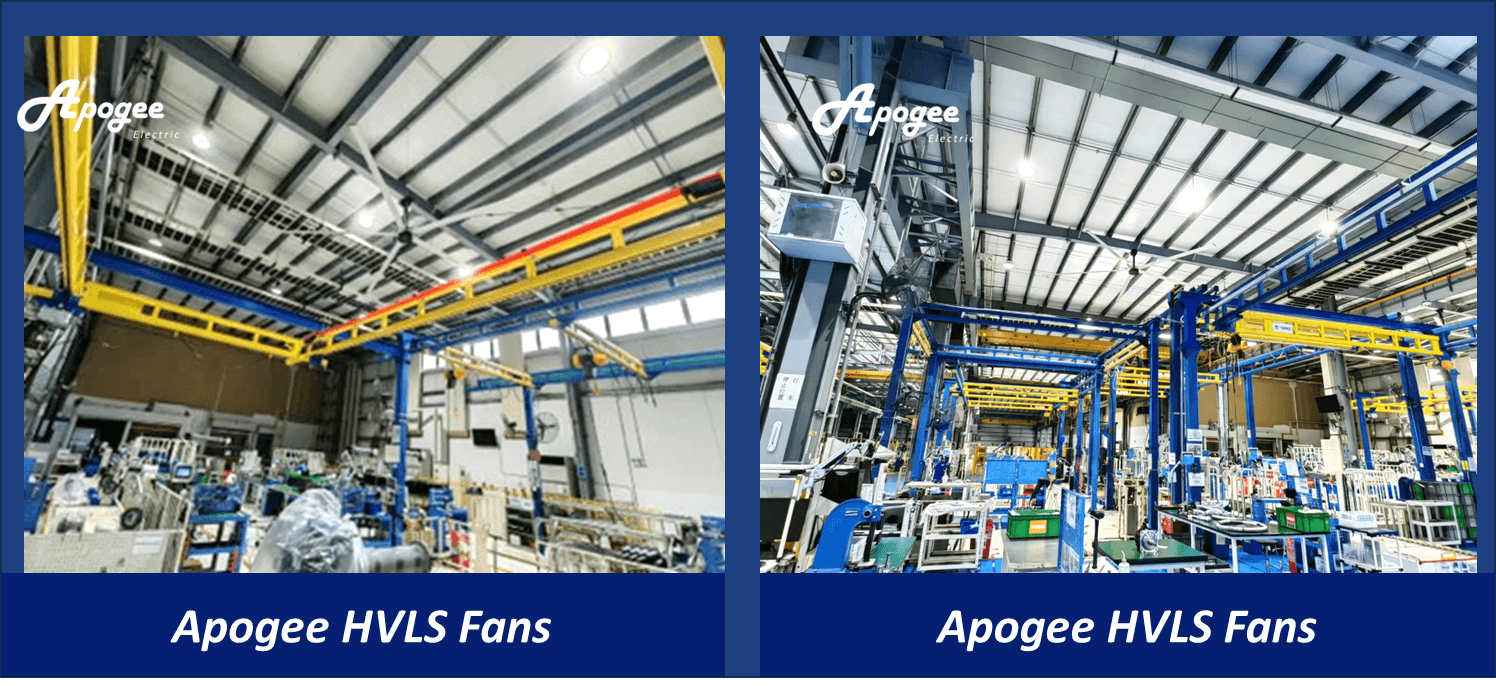

In the operation of modern factories, managers are constantly confronted with some thorny and interrelated pain points: persistently high energy bills, employees’ complaints in harsh environments, damage to production quality due to environmental fluctuations, and increasingly urgent energy conservation and emission reduction targets. These are not insignificant minor issues but key challenges that directly affect the core competitiveness of enterprises. It is delightful to see that a seemingly simple yet highly intelligent solution is hanging high above the factory building – that is the high-performance large low-speed Fan (HVLS Fan). It is not merely a “passing breeze”, but a powerful tool to systematically address the pain points of these factories.

Challenges 1: Huge energy consumption, high costs for cooling in summer and heating in winter.

The limitations of traditional solutions: In huge factory Spaces, the cost of using traditional air conditioners for cooling is extremely high. In winter, due to the natural rise of hot air, high-temperature areas form beneath the rooftops, while the ground areas where people are active remain cold.

HVLS solution

The HVLS fan, through the slow rotation of its huge blades, pushes a large amount of airflow downward, forming an effective airflow circulation. In winter, it gently pushes the hot air accumulated on the roof towards the ground, completely eliminating temperature stratification. This can achieve even heat distribution and save up to 20-30% of heating costs. In summer, the continuous air flow produces an evaporative cooling effect on the surface of employees’ skin, bringing a significant perceived temperature drop, making people feel 5 to 8 degrees Celsius cooler, thereby reducing or even replacing the use of some high-energy-consuming air conditioners. Its single power consumption is only equivalent to that of a household incandescent light bulb, yet it can cover an area of thousands of square meters, with an extremely high return on investment.

Challenges 2: Unstable product quality and damage to temperature and humidity sensitive materials

The limitations of traditional solutions: For many industries, such as precision manufacturing, food processing, pharmaceutical warehousing, textile and wood processing, fluctuations in environmental temperature and humidity are the “invisible killers” of product quality. Wood may deform due to uneven humidity, food may deteriorate more rapidly, and precision electronic components may get damp. All these can lead to huge losses and cost waste.

HVLS solution

The core function of the HVLS fan is air Destratification. It keeps the temperature and humidity from the floor to the ceiling of the factory building highly uniform and consistent through continuous and gentle stirring. This provides a stable and predictable storage and production environment for temperature and humidity sensitive materials and products, greatly reducing product deterioration, corrosion or deformation caused by environmental changes, and directly protecting the core assets and profits of enterprises.

Challenges 3: Harsh production environment, employees suffer from heat stress, low efficiency and high health risks

The limitations of traditional solutions: Workshops with high temperatures, stuffiness and stagnant air are the number one enemy of efficiency and safety. Employees are prone to fatigue and inattentiveness, which not only leads to a decline in productivity but also makes them more likely to suffer from occupational health problems such as heatstroke. At the same time, stagnant air means that dust, smoke and volatile organic compounds (VOCs) are difficult to disperse, which poses a long-term threat to the respiratory health of employees.

HVLS solution

The all-round and seamless breeze created by HVLS fans can effectively reduce employees’ heat stress response and keep the perceived temperature within a comfortable range. Employees feel cooler, more concentrated, have a lower error rate, and their work efficiency and morale naturally improve. More importantly, continuous air circulation can break the accumulation of dust and smoke, pushing them towards the exhaust system or diluting them to a safe concentration, significantly improving indoor air quality and creating a healthier and safer working environment for employees.

The Challenges in factories are often systemic, and HVLS fans offer precisely a systematic intelligent solution. It transcends the concept of traditional ventilation equipment and has become an integrated platform that combines energy conservation and consumption reduction, environmental improvement, quality assurance, and employee care. Investing in HVLS fans is no longer merely about purchasing a piece of equipment; it is a strategic investment in the operational efficiency of the enterprise, the health of employees, and a sustainable future. It transforms the once “cost pain point” into a “value engine” that drives the enterprise forward.

Post time: Sep-16-2025