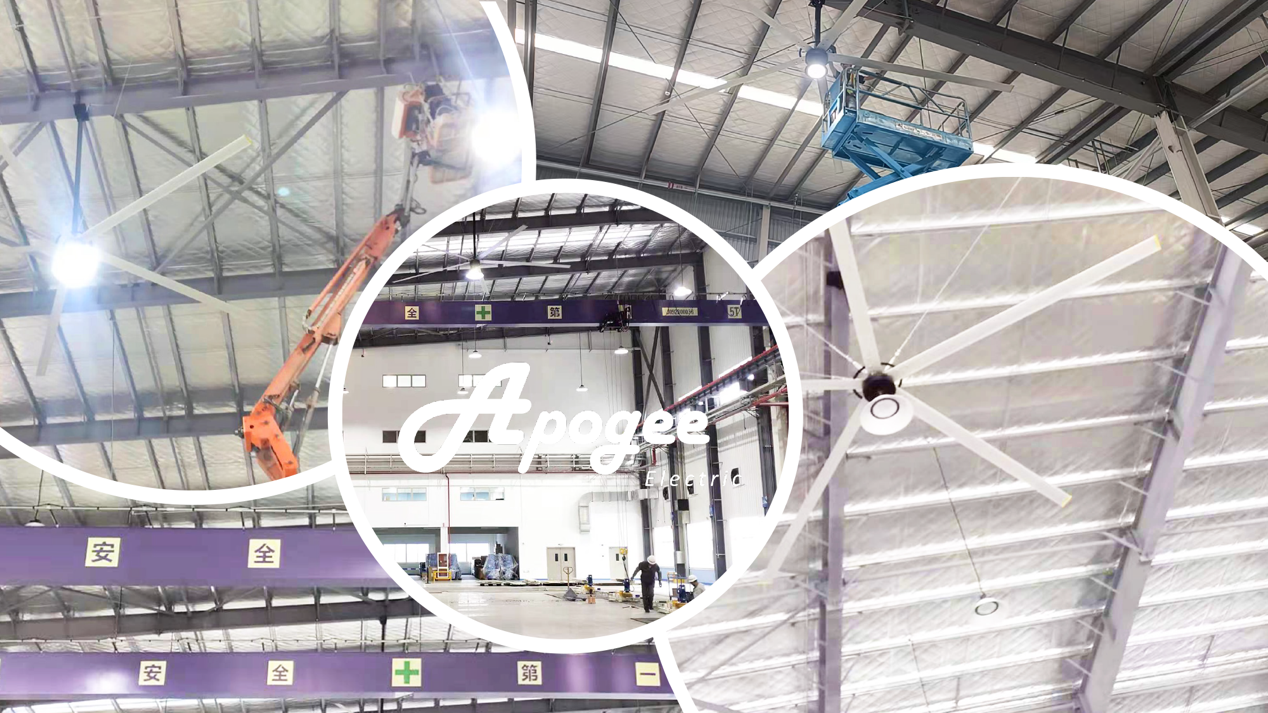

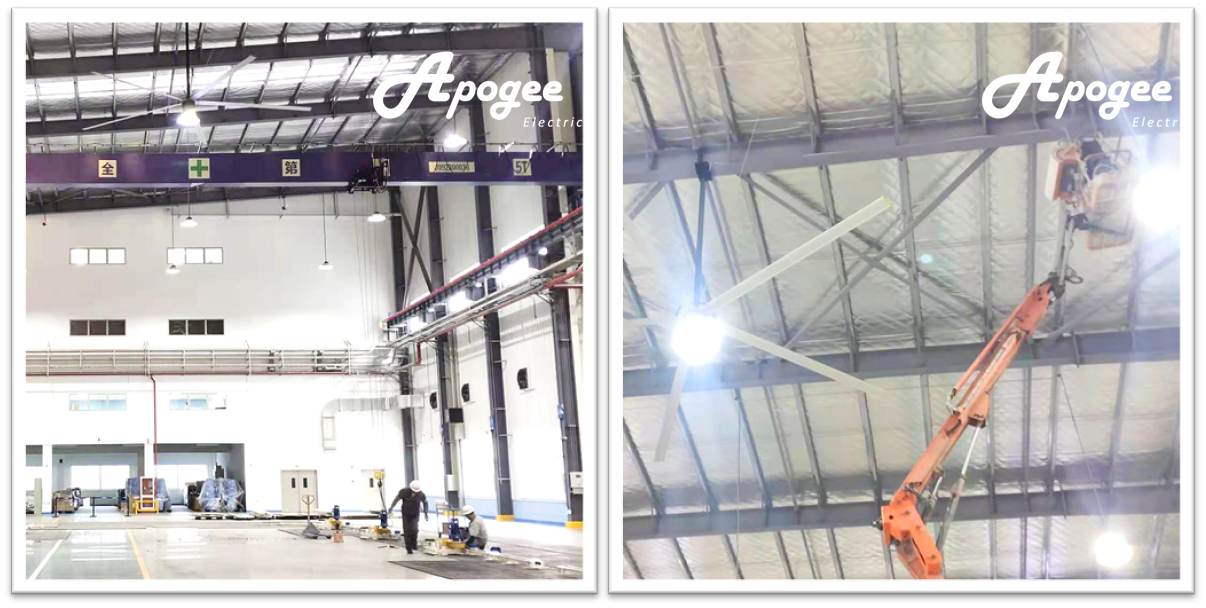

Many modern factories, especially newly-built or renovated warehousing, logistics and manufacturing centers, are increasingly inclined to choose HVLS fans with LED Lights. This is not merely a simple addition of functions, but a well-considered strategic decision.

In simple terms, factories choose HVLS fans with LED Lights (i.e., industrial large ceiling fans with integrated LED lighting) mainly to achieve triple optimization of space, energy and management, while completely solving the problems of glare and flicker between fan blades and lights.

1. Address fundamental issues: Completely eliminate “light shadows” and stroboscopic effects

This is the most core and direct technological advantage. In traditional factory layouts, high ceiling lights and large fans are installed separately, which can easily cause uncomfortable or even dangerous stroboscopic effects.

How to solve the problem of HVLS with light: The LED light board is directly installed at the center position below the fan motor, and becomes a synchronous moving whole with the fan. Since the relative position of the lamp and the blade is fixed, the blade will no longer cut the stationary light source from above, thus fundamentally eliminating stroboscopic shadows. This creates a safer and more comfortable working environment, especially for areas that require the operation of precision machinery.

2. Space utilization and infrastructure optimization

Save space and avoid interference: In tall and spacious factory buildings, installing lighting poles separately will occupy precious ground space, affecting the passage of forklifts, the stacking of goods and the layout of production lines. The illuminated fan integrates all functions at one point on the roof, freeing up all the floor space.

Simplify the roof structure: There is no need to design two separate sets of hoisting structures and cable wiring for lamps and fans. Only a more robust hoisting system is needed to carry the fan, along with a set of power lines. This simplifies the roof design and reduces potential structural interference points (such as conflicts with fire protection ducts, air conditioning ducts, and trusses).

3. Significant energy conservation and cost-effectiveness (1+1 > 2)

This is a point that factory managers attach great importance to.

Dual energy-saving effect

● HVLS Fan Energy Saving: HVLS fans stir a large amount of air through huge fan blades, achieving efficient destratification (Destratification/air convection). In winter, it pushes the hot air accumulated on the roof to the ground, reducing heating energy consumption. In summer, it creates an evaporative cooling effect, reducing the load on air conditioners.

● Lighting energy conservation: It integrates the most advanced LED technology. Compared with traditional metal halide lamps or high-pressure sodium lamps, energy consumption can be reduced by more than 50%.

Single power supply, reducing installation costs: Fans and lighting share one circuit, reducing installation costs such as cables, conduits (conduits), and wiring hours, saving expenses from the very beginning of the project.

4. Improvement in lighting quality and work efficiency

● High-quality light source: Integrated LED lights can more accurately reproduce the colors of objects, reduce visual fatigue, and are crucial for work processes such as quality inspection, sorting, and assembly that require fine vision, helping to enhance work accuracy and efficiency.

● Non-glare design: The light shines vertically downward from above, avoiding the glare caused by direct exposure of lateral light sources to the human eye.

● Uniform light distribution: By rationally planning the layout of the fans, it can be ensured that the lighting areas beneath them are interconnected, forming a uniform and blind-spot-free lighting environment, and eliminating the zebra crossing shadows under traditional high-ceiling lamp lighting.

5. Convenience of operation and maintenance

● Centralized control: It is convenient to use a single control system. For instance, only the lights can be turned on without the fans, or different scene modes can be set.

● Simplified maintenance: The maintenance team only needs to maintain one integrated device instead of tracking the maintenance cycles of fans and lamps separately. Moreover, due to the adoption of long-life Leds, the maintenance requirements for the lighting part are extremely low.

If you want to be our distributor, please contact us through WhatsApp: +86 15895422983.

Post time: Sep-23-2025