What are HVLS fans used for in cow farm?

In modern dairy farming, maintaining optimal environmental conditions is crucial for animal health, productivity, and operational efficiency. High Volume, Low Speed (HVLS) fans have emerged as a transformative technology in barn management, addressing challenges ranging from heat stress to air quality. These HVLS fans (typically 20–24 feet) operate at low rotational speeds while moving vast volumes of air, offering multifaceted benefits tailored to the unique needs of cattle housing.

What are HVLS fans used for in cow farm?

1. Combatting Heat Stress: A Lifeline for Milk Production

Cattle, particularly dairy cows, are highly sensitive to heat. When temperatures exceed 20°C (68°F), cows begin to experience heat stress, leading to reduced feed intake, decreased milk yield, and impaired fertility.

• By moving large volumes of air, HVLS fans promote evaporative coolinrespiratory surfaces, reducing heat stress. Thig from cows' skin and s is critical as heat stress lowers milk production, feed intake, and reproductive efficiency.

• Proper airflow can reduce a cow’s perceived temperature by 5–7°C, directly correlating with improved milk production—dairy farms using HVLS systems often report 10–15% increases in milk yield during summer months. By preventing panting and metabolic strain, these fans also reduce the risk of secondary health issues like acidosis.

2. Air Quality Management: Mitigating Respiratory Risks

Confined barn environments accumulate harmful gases such as ammonia (from urine), methane (from manure), and hydrogen sulfide. Prolonged exposure to these gases can cause respiratory diseases, reduced immunity, and chronic stress.

• HVLS fans disrupt gas stratification by continuously mixing air, diluting contaminants, and promoting ventilation. This minimizes respiratory issues and inhibits pathogen growth, fostering a healthier environment.

• Reduce humidity by accelerating the evaporation of moisture from bedding, floors, and water troughs. Lower humidity (ideally maintained at 60–70%) not only discourages pathogen proliferation (e.g., mastitis-causing bacteria) but also prevents slippery surfaces, reducing injury risks.

3. Seasonal Versatility: Winter Destratification

The problem in winter is that the heat produced is full of humidity and ammonia. If kept trapped inside, it will produce condensation that, in extreme cases, will actually create clouds of steam within the building. This condensation can also freeze and create ice build-up on the inside of the sidewall curtains or panels, which leads to potential hardware failure due to the increased weight.

• HVLS fans reverse this by gently pushing trapped warm air downward, ensuring uniform temperatures throughout the barn, reducing heating fuel costs by 10–20%

• Preventing condensation and frostbite risks in uninsulated facilities.

4. Spray water with HVLS Fan Cooling Systems

In regions with extreme heat, HVLS fans are often paired with evaporative cooling systems. For instance, misters release fine water droplets into the air, which the fans then distribute evenly. The combined effect enhances evaporative cooling efficiency by up to 40%, creating a microclimate akin to a “cooling breeze” without drenching bedding—critical for preventing hoof diseases like digital dermatitis. Similarly, in facilities with tunnel ventilation, HVLS fans can assist in directing airflow patterns to eliminate dead zones.

5. A Single Controller for All Your Equipment

The Apogee controller provides the opportunity to oversee a multitude of input and output factors within your dairy. The system automates the operation of all your equipment according to customized parameters. It also lets you take advantage of essential real-time data to make strong and effective decisions. This smart system simplifies the management of your dairy facilities to maximize your use of time.

Apogee Controller

More than a Ventilation Controller

The Maximus controller manages:

• Ventilation

• Weather station

• Temperature, humidity auto control

• Lights

• 485 communication

• And much more

Additional Benefits

Scalable system, up to 20 fans

• Remote management

• Customizable reports

• Multilingual

• Free updates

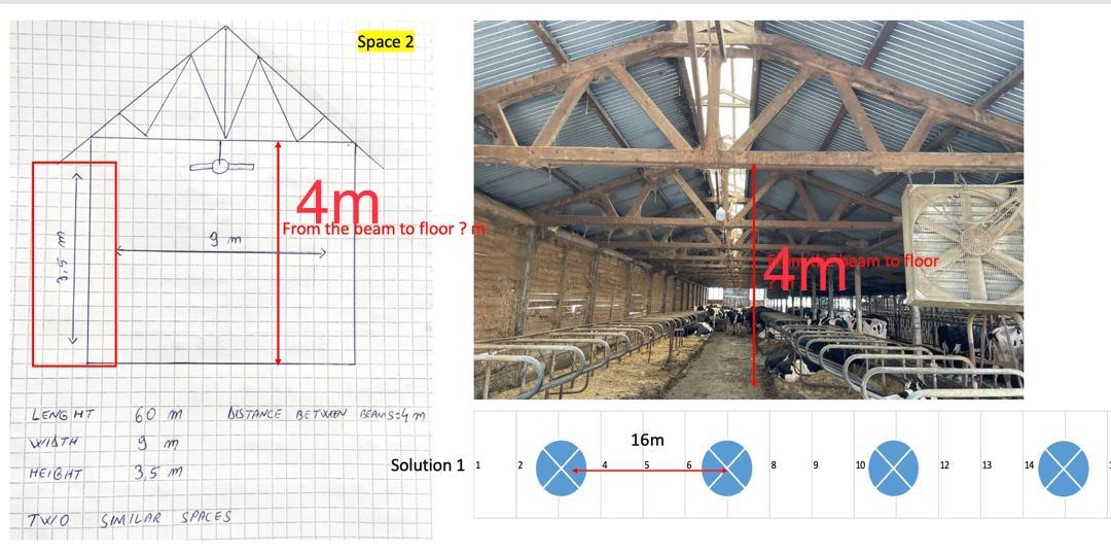

6. Case Study: Fan solution for a cow farm

Width * Length*Height : 60 x 9 x 3.5m

20ft (6.1m) fan*4sets, Centre distance between two fans is 16m.

Model Number: DM-6100

Diameter: 20ft(6.1m), Speed: 10-70rpm

Air volume: 13600m³/min, Power: 1.3kw

HVLS fans reduced average barn temperatures by 4°C during peak summer after installed. Milk production rose by 1.2 kg/cow/day, while veterinary costs for respiratory issues dropped by 18%. The farm recouped its investment in under two years through energy savings and productivity gains.

HVLS fans are not merely cooling devices but holistic environmental management tools. By addressing thermal comfort, air quality, energy use, and animal behavior, they elevate both welfare standards and farm profitability. As climate challenges intensify, adopting such technologies will be pivotal for sustainable, high-output dairy operations.

If you have cow farm ventilation inquiry, please contact us through WhatsApp: +86 15895422983.

Post time: May-09-2025