If you’re managing a factory or warehouse with an overhead crane system, you’ve likely asked a critical question: "Can we install an HVLS (High-Volume, Low-Speed) fan without interfering with crane operations?”

The short answer is a resounding yes. Not only is it possible, but it is also one of the most effective ways to improve air circulation, enhance worker comfort, and reduce energy costs in large, high-bay industrial spaces. The key lies in careful planning, precise installation, and understanding the synergy between these two essential systems.

This guide will walk you through everything you need to know about safely and effectively installing an HVLS fan in a facility with an overhead crane.

Understanding the Challenge: Fan vs. Crane

The primary concern is, of course, clearance. An HVLS fan requires significant vertical space for its large diameter (ranging from 8 to 24 feet), while an overhead crane needs a clear path to travel the length of the building without obstruction.

A collision between a crane and a fan would be catastrophic. Therefore, the installation must be designed to eliminate any possibility of interference.

Solutions for Safe Coexistence: Installation Methods

1. Mounting to the Main Building Structure

This is the most common and often preferred method. The HVLS fan is suspended from the roof structure (e.g., a rafter or truss) independently of the crane system.

- How it Works: The fan is installed high enough that its lowest point (the blade tip) sits above the top-most travel path of the crane and its hook. This creates a permanent, safe clearance.

- Best For: Most top-running overhead bridge cranes where there is sufficient height between the roof structure and the crane's runway.

- Key Advantage: Completely decouples the fan system from the crane system, ensuring zero risk of operational interference.

2. Clearance and Height Measurements

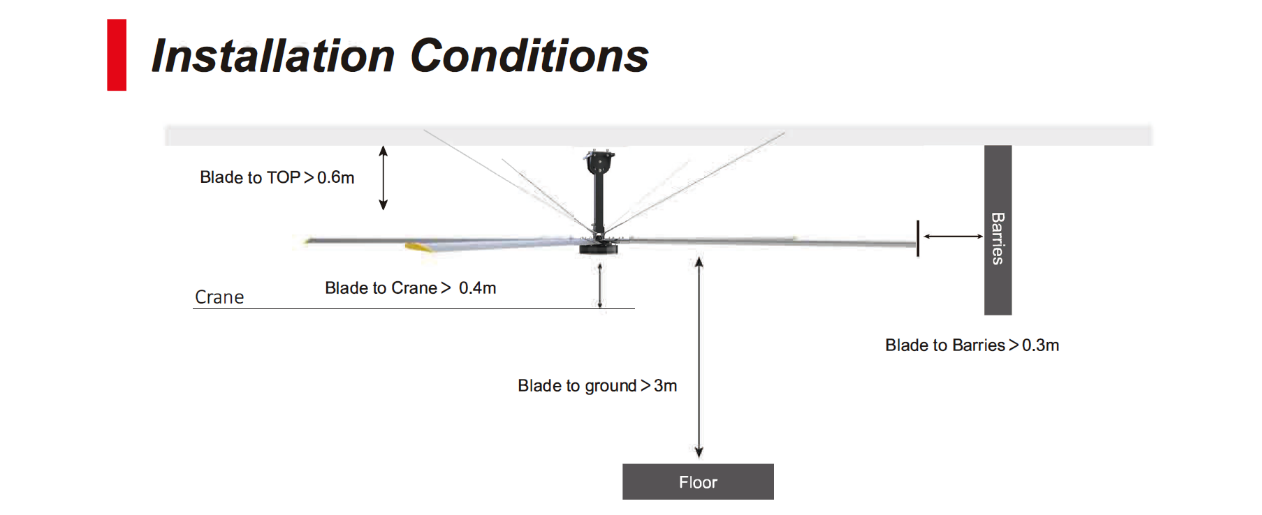

There is a minimum space requirement 3-5 feet as a safety to install HVLS Fan above the crane. Generally speaking the more space the better. You must precisely measure the space, and it’s the most critical step. Building Eave Height: The height from the floor to the bottom of the roof.

- Crane Hook Lift Height: The highest point the crane hook can reach.

- Fan Diameter and Drop: The total height of the fan assembly from the mounting point to the lowest blade tip.

The formula for a structurally-mounted fan is simple: Mounting Height > (Crane Hook Lift Height + Safety Clearance).

3. Fan Extension Rod Selection and Coverage

Apogee HVLS Fan is with PMSM direct drive motor, the height of the HVLS fan is much shorter than traditional gear drive type. The height of the fan is mostly length of the extension rod. In order to get a most effective coverage solution, and making sure there is enough safety space, we suggest to select a suitable extension rod, and need to consider the safety space between the blade tip and crane (0.4m~-0.5m). For example, if the space between I-beam to crane is 1.5m, we suggest to select extension rod 1m, if in another case the space between I-beam to crane is 3m, we suggest to select extension rod 2.25~2.5m. So the blades can be closer to floor and get bigger coverage.

The Powerful Benefits of Combining HVLS Fans with Cranes

Overcoming the installation challenge is well worth the effort. The benefits are substantial:

- Improved Worker Comfort and Safety: Moving large volumes of air prevents stagnant, hot air from pooling at the ceiling (destratification) and creates a cooling breeze at the floor level. This reduces heat-related stress and improves morale for workers on the floor and even crane operators.

- Enhanced Productivity: A comfortable workforce is a more productive and focused workforce. Proper ventilation also reduces fumes and moisture.

- Significant Energy Savings: By destratifying heat in the winter, HVLS fans can reduce heating costs by up to 30%. In the summer, they allow for thermostat set-points to be raised, reducing air conditioning costs.

- Protection of Assets: Consistent airflow helps control moisture, reducing the risk of rust on equipment, machinery, and the crane itself.

FAQs: HVLS Fans and Cranes

Q: What is the minimum safe clearance between a fan blade and a crane?

A: There is no universal standard, but a minimum of 3-5 feet is often recommended as a safety buffer to account for any potential sway or miscalculation. Your HVLS fan manufacturer will provide a specific requirement.

Q: Can a crane-mounted fan be connected to power?

A: Yes. This is typically done using a specially designed crane electrification system, such as a festoon system or conductor bar, which provides continuous power as the crane and fan move.

Q: Who should handle the installation?

A: Always use a certified and experienced installer who specializes in HVLS fans for industrial applications. They will work with structural engineers and your facility team to ensure a safe, code-compliant installation.

Conclusion

Integrating an HVLS fan into a factory with an overhead crane is not only feasible but highly advantageous. By choosing the correct installation method—structural mounting for broad coverage or crane mounting for targeted airflow—and adhering to strict safety and engineering protocols, you can unlock the full potential of improved air movement.

The result is a safer, more comfortable, and more efficient working environment that pays for itself in boosted productivity and slashed energy bills.

Post time: Nov-05-2025