Are bigger HVLS fans better in Workshop?

Bigger HVLS (High Volume, Low Speed) fans can be advantageous in workshops, but their suitability depends on the specific needs and layout of the space. Here’s a breakdown of when and why larger HVLS fans might be better, along with key considerations:

Advantages of Larger HVLS Fans in Workshops:

• Greater Airflow Coverage

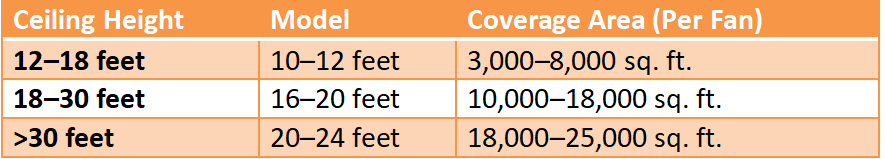

Large Diameter Blades (e.g., 20–24 feet) move massive volumes of air at low speeds, creating a wide column of airflow that can cover expansive areas (up to 20,000+ sq. ft. per fan).

One of the primary benefits of installing Apogee HVLS industrial ceiling fan is improved air circulation. Workshop often have high ceilings and large floor areas, which can lead to stagnant air pockets. Apogee HVLS fan helps to distribute air evenly throughout the space, it’s noise ≤38db, very quiet. Apogee HVLS Fans reducing hot spots and ensuring a more comfortable working environment. This is particularly important in industries where employees are engaged in physically demanding tasks.

Ideal for High Ceilings: Workshops with ceiling heights of 15–40+ feet benefit most, as larger fans push air downward and horizontally to destratify air (mixing hot/cold layers) and maintain consistent temperatures.

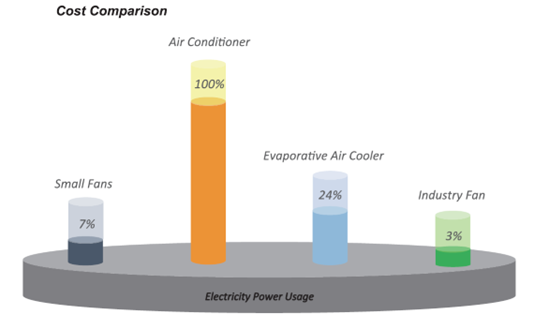

• Energy Efficiency

A single large HVLS fan often replaces multiple smaller fans, reducing energy consumption. Their low-speed operation (60–110 RPM) uses less power than traditional high-speed fans.

• Comfort & Safety

Gentle, widespread airflow prevents stagnant zones, reduces heat stress, and improves worker comfort without creating disruptive drafts.

Quiet operation (60–70 dB) minimizes noise pollution in busy workshops.

• Dust & Fume Control

By circulating air uniformly, larger HVLS fans help disperse airborne particulates, fumes, or humidity, improving air quality and drying floors faster.

• Year-Round Use

In winter, they destratify warm air trapped near the ceiling, redistributing heat and cutting heating costs by up to 30%.

Key Considerations for Workshop HVLS Fans

* Ceiling Height:

Match fan diameter to ceiling height (e.g., 24-ft fan for 30-ft ceilings).

* Workshop Size & Layout:

Calculate coverage needs (1 large fan vs. multiple smaller ones).

Avoid obstructions (e.g., cranes, ductwork) that disrupt airflow.

* Airflow Goals:

Prioritize destratification, worker comfort, or contaminant control.

* Energy Costs:

Larger fans save energy long-term but require higher initial investment.

* Safety:

Ensure proper mounting, clearance, and blade guards for worker safety.

Example Scenarios

Large, Open Workshop (50,000 sq. ft., 25-ft ceilings):

A few 24-ft HVLS fans would efficiently destratify air, reduce HVAC costs, and improve comfort.

Small, Cluttered Workshop (10,000 sq. ft., 12-ft ceilings):

Two or three 12-ft fans may provide better coverage around obstructions.

Conclusion:

Bigger HVLS fans are often better in large, high-ceilinged workshops with open layouts, offering unmatched airflow coverage and energy savings. However, smaller HVLS fans or a hybrid system may be more practical in constrained spaces or for targeted needs. Always consult an HVAC specialist to model airflow and optimize fan size, placement, and quantity for your specific workshop.

Post time: May-28-2025