Uma uphatha ifektri noma i-warehouse enesistimu ye-crane ephezu kwekhanda, kungenzeka ukuthi ubuze umbuzo obalulekile:"Singakwazi yini ukufaka ifeni ye-HVLS (High-Volume, Low-Speed) ngaphandle kokuphazamisa ukusebenza kwe-crane?"

Impendulo emfushane iyamangalisayebo.Akukhona nje kuphela ukuthi kungenzeka, kodwa futhi kungenye yezindlela eziphumelela kakhulu zokuthuthukisa ukujikeleza komoya, ukuthuthukisa induduzo yabasebenzi, nokunciphisa izindleko zamandla ezindaweni ezinkulu zezimboni ezinamanzi aphezulu. Isihluthulelo sisekuhleleni ngokucophelela, ekufakweni okunembile, nasekuqondeni ukusebenzisana phakathi kwalezi zinhlelo ezimbili ezibalulekile.

Lo mhlahlandlela uzokuqondisa kukho konke okudingeka ukwazi mayelana nokufaka i-Ifeni ye-HVLSendaweni ene-crane ephezu kwendlu.

Ukuqonda Inselele: Umlandeli vs. I-Crane

Ukukhathazeka okuyinhloko, vele,imvume. Ifeni ye-HVLS idinga isikhala esikhulu esiqondile sobubanzi bayo obukhulu (kusuka kumamitha angu-8 kuya kwangu-24), kuyilapho i-crane ephezu kwendlu idinga indlela ecacile ukuze ihambe ubude besakhiwo ngaphandle kokuphazanyiswa.

Ukungqubuzana phakathi kwe-crane nefeni kungaba yinhlekelele enkulu. Ngakho-ke, ukufakwa kumele kwakhiwe ukuze kuqedwe noma yikuphi ukuphazamiseka okungenzeka.

Izixazululo Zokuhlala Ngokuphepha: Izindlela Zokufaka

1. Ukufakwa Esakhiweni Esiyinhloko Sesakhiwo

Lena yindlela evame kakhulu futhi evame ukuthandwa. Ifeni ye-HVLS ilenga esakhiweni sophahla (isb., ugongolo noma i-truss)ngokuzimela ohlelweni lwe-crane.

- Indlela Esebenza Ngayo:Ifeni ifakwe phezulu ngokwanele ukuthi iphuzu layo eliphansi kakhulu (isihloko se-blade) lihlala phansingaphezu kwendlela yokuhamba ehamba phambili ye-crane kanye ne-hook yayoLokhu kudala indawo ephephile nehlala njalo.

- Okuhle Kakhulu Ku:Ama-crane amaningi ebhuloho asebenza phezulu lapho kunokuphakama okwanele phakathi kwesakhiwo sophahla kanye nendlela yokugijima ye-crane.

- Inzuzo Eyinhloko:Ihlukanisa ngokuphelele uhlelo lwefeni ohlelweni lwe-crane, iqinisekisa ukuthi akukho bungozi bokuphazamiseka kokusebenza.

2. Ukulinganisa Ukukhanya Nokuphakama

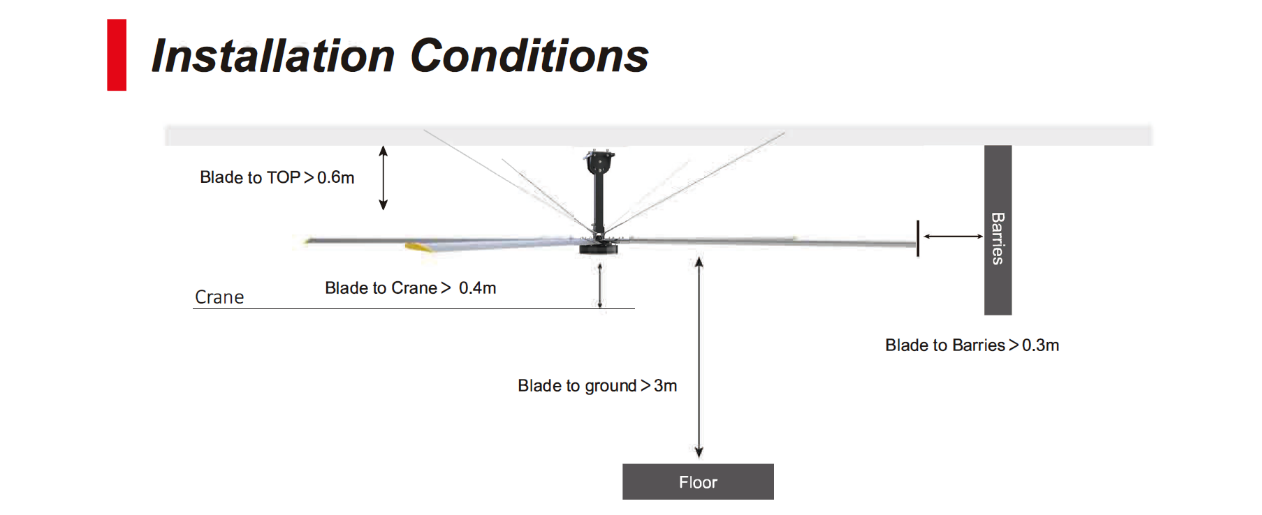

Kunesidingo sesikhala esincane esingamamitha angu-3-5 njengokuphepha kokufaka i-HVLS Fan ngaphezu kwe-crane. Ngokuvamile uma isikhala sisikhulu kungcono. Kumelwe ulinganise isikhala ngokunembile, futhi yisinyathelo esibaluleke kakhulu.Ukuphakama kwe-Eave yesakhiwo:Ukuphakama kusukela phansi kuya phansi kophahla.

- Ukuphakama Kokuphakamisa I-Crane Hook:Iphuzu eliphakeme kakhulu elingafinyelelwa yi-crane hook.

- Ububanzi kanye Nokwehla Kwabalandeli:Ukuphakama okuphelele kwenhlangano yefeni kusukela endaweni yokufaka kuya encazelweni ye-blade ephansi kakhulu.

Ifomula yefeni efakwe ngendlela ehlelekile ilula:Ukuphakama Kokukhweza > (Ukuphakama Kokuphakamisa I-Crane Hook + Ukususwa Kokuphepha).

3. Ukukhethwa Nokumbozwa Kwenduku Yokwelulwa Kwabalandeli

I-Apogee HVLS Fan inenjini ye-PMSM direct drive, ukuphakama kwefeni ye-HVLS kufushane kakhulu kunohlobo lwegiya lendabuko. Ukuphakama kwefeni ikakhulukazi ubude benduku yokwelula. Ukuze sithole ikhambi lokumboza elisebenza kahle kakhulu, futhi siqinisekise ukuthi kunesikhala esanele sokuphepha, siphakamisa ukuthi kukhethwe induku yokwelula efanele, futhi sidinga ukucabangela isikhala sokuphepha phakathi kwesihloko se-blade kanye ne-crane (0.4m~-0.5m). Isibonelo, uma isikhala esiphakathi kwe-I-beam ne-crane singama-1.5m, siphakamisa ukuthi kukhethwe induku yokwelula engu-1m, uma kwesinye isimo isikhala esiphakathi kwe-I-beam ne-crane singama-3m, siphakamisa ukuthi kukhethwe induku yokwelula engu-2.25~2.5m. Ngakho-ke ama-blade angasondela phansi futhi athole ukumbozwa okukhulu.

Izinzuzo Ezinamandla Zokuhlanganisa Amafeni E-HVLS Nama-Cranes

Ukunqoba inselele yokufaka kuwufanele umzamo. Izinzuzo zinkulu:

- Induduzo Nokuphepha Kwabasebenzi Okuthuthukisiwe:Ukuhambisa umoya omningi kuvimbela umoya oshisayo ongahlali ndawonye ophahleni (ukubhujiswa) futhi kudala umoya opholile ezingeni lephansi. Lokhu kunciphisa ukucindezeleka okuhlobene nokushisa futhi kuthuthukisa isimilo sabasebenzi abaphansi ngisho nabasebenzi be-crane.

- Ukukhiqiza Okuthuthukisiwe:Abasebenzi abakhululekile bangabantu abakhiqizayo nabagxile kakhulu. Umoya ofanele unciphisa umusi kanye nomswakama.

- Ukonga Okuphawulekayo Kwamandla:Ngokuqeda ukushisa ebusika, amafeni e-HVLS anganciphisa izindleko zokushisa ngamaphesenti afinyelela ku-30. Ehlobo, avumela ukuthi kukhushulwe ama-thermostat, okunciphisa izindleko zomoya opholile.

- Ukuvikelwa Kwempahla:Ukuhamba komoya njalo kusiza ukulawula umswakama, kunciphisa ingozi yokugqwala emishinini, emishinini, kanye nase-crane uqobo.

Imibuzo Evame Ukubuzwa: Amafeni Nama-Crane e-HVLS

Q: Iyiphi indawo encane ephephile phakathi kwe-fan blade ne-crane?

A:Ayikho indinganiso evamile, kodwa ubuncane bamamitha angu-3-5 buvame ukunconywa njengesivikelo sokuphepha ukuze kubhekwe noma yikuphi ukushukuma okungenzeka noma ukungabaleki kahle.Ifeni ye-HVLSumenzi uzohlinzeka ngemfuneko ethile.

Q: Ingabe ifeni efakwe ku-crane ingaxhunywa kugesi?

A:Yebo. Lokhu kuvame ukwenziwa kusetshenziswa i-uhlelo lokufaka ugesi lwe-crane, njengohlelo lwe-festoon noma ibha yomqhubi, enikeza amandla aqhubekayo njengoba i-crane kanye nefeni zihamba.

U: Ubani okufanele aphathe ukufakwa?

A:Sebenzisa njalo umfaki oqinisekisiwe futhi onolwazi ogxile kumafeni e-HVLS ezinhlotsheni zezimboni. Bazosebenzisana nonjiniyela bezakhiwo kanye nethimba lesikhungo sakho ukuqinisekisa ukufakwa okuphephile nokuhambisana nemithetho.

Isiphetho

Ukuhlanganisa ifeni ye-HVLS efektri ene-crane ephezu kwendlu akugcini nje ngokuba yinto engenzeka kodwa futhi kunenzuzo enkulu. Ngokukhetha indlela efanele yokufaka—ukufakwa kwesakhiwo ukuze kuhlanganiswe kabanzi noma ukufakwa kwe-crane ukuze kugeleze umoya okuqondiwe—futhi ulandela izinqubo zokuphepha eziqinile nezobunjiniyela, ungavula amandla aphelele okunyakaza komoya okuthuthukisiwe.

Umphumela uba yindawo yokusebenza ephephile, ekhululekile, futhi esebenza kahle kakhulu ezikhokhela umkhiqizo okhulisiwe kanye nezindleko zamandla ezincishisiwe.

Isikhathi sokuthunyelwe: Novemba-05-2025