Ukuba ulawula umzi-mveliso okanye indawo yokugcina impahla enenkqubo yekreni ephezu kwentloko, kusenokwenzeka ukuba ubuze umbuzo obalulekileyo:"Singayifaka ifeni yeHVLS (High-Volume, Low-Speed) ngaphandle kokuphazamisana nokusebenza kwekreyini?"

Impendulo emfutshane iyamangalisaEwe.Ayipheleli nje ekubeni inokwenzeka, kodwa ikwayenye yezona ndlela zisebenzayo zokuphucula ukujikeleza komoya, ukuphucula intuthuzelo yabasebenzi, kunye nokunciphisa iindleko zamandla kwiindawo ezinkulu zemizi-mveliso ezineengca eziphezulu. Isitshixo sisekucwangciseni ngononophelo, ukufakelwa ngokuchanekileyo, kunye nokuqonda ukusebenzisana phakathi kwezi nkqubo zimbini zibalulekileyo.

Esi sikhokelo siza kukubonisa yonke into ekufuneka uyazi malunga nokufakela ngokukhuselekileyo nangokufanelekileyoIfeni ye-HVLSkwindawo enekreni ephezu kwentloko.

Ukuqonda uMngeni: Umlandeli vs. uCrane

Eyona nkxalabo iphambili kukuba, ewe,imvumeIfeni ye-HVLS ifuna indawo enkulu ethe nkqo kwi-diameter yayo enkulu (ukusuka kwi-8 ukuya kwi-24 iinyawo), ngelixa ikreyini ephezu komhlaba ifuna indlela ecacileyo yokuhamba ubude besakhiwo ngaphandle kokuphazanyiswa.

Ukungqubana kwe-crane nefeni kungaba yintlekele enkulu. Ngoko ke, ukufakelwa kufuneka kuyilwe ukuze kupheliswe naluphi na uphazamiseko olunokwenzeka.

Izisombululo Zokuhlala Ngokukhuselekileyo: Iindlela Zokufaka

1. Ukufakelwa kwiSakhiwo esiPhambili seSakhiwo

Le yeyona ndlela ixhaphakileyo nethandwa kakhulu. Ifeni yeHVLS ixhonywe kwisakhiwo sophahla (umz., umqadi okanye i-truss)ngokuzimeleyo kwenkqubo yekreyini.

- Ingaba isebenza kanjani:Ifeni ifakwe phezulu ngokwaneleyo ukuba indawo yayo ephantsi (incam yeblade) ihlalengaphezulu kwendlela ehamba phambili yokuhamba yekreni kunye nehoko yayoOku kudala indawo ehlala ikhuselekile kwaye ikhuselekile.

- Eyona ilungileyo:Uninzi lweekhreyini zebhulorho ezihamba ngaphezulu apho kukho ukuphakama okwaneleyo phakathi kwesakhiwo sophahla kunye nendlela yekreyini.

- Inzuzo ephambili:Iyasusa ngokupheleleyo inkqubo yefeni kwinkqubo yekreyini, iqinisekisa ukuba akukho mngcipheko wokuphazamiseka kokusebenza.

2. Ubungakanani bokucaca kunye nokuphakama

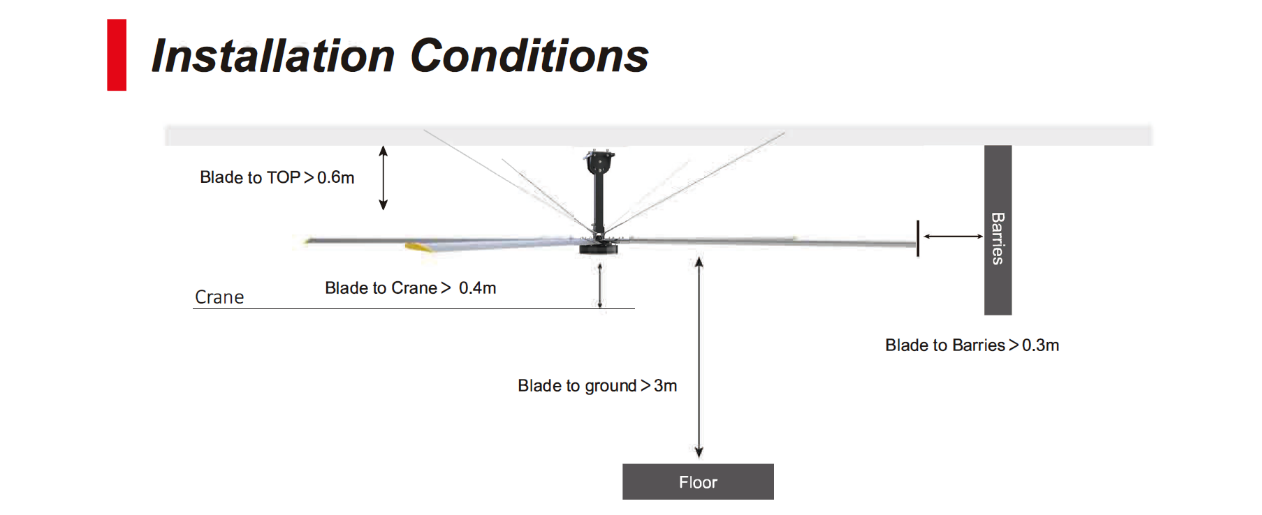

Kukho imfuneko encinci yesithuba esingangeemitha ezi-3-5 njengokhuseleko lokufakela i-HVLS Fan ngaphezulu kwe-crane. Ngokubanzi, okukhona indawo ininzi kokukhona kungcono. Kufuneka ulinganise indawo ngokuchanekileyo, kwaye lelona nyathelo libalulekileyo.Ukuphakama kwe-Eave yesakhiwo:Ukuphakama ukusuka kumgangatho ukuya ezantsi kophahla.

- Ukuphakama kweCrane Hook Lift:Eyona ndawo iphezulu enokufikelelwa yi-crane hook.

- Ububanzi befeni kunye nokuwa:Ukuphakama okupheleleyo kwendibano yefeni ukusuka kwindawo yokuxhoma ukuya kwincam yeblade esezantsi.

Ifomula yefeni efakwe ngokwesakhiwo ilula:Ukuphakama Kokukhwelisa > (Ukuphakama Kokuphakamisa I-Crane Hook + Ukususwa Kokhuseleko).

3. Ukukhethwa kwentonga yolwandiso lwefeni kunye nokugqunywa kwayo

I-Apogee HVLS Fan inenjini ye-PMSM direct drive, ukuphakama kwefeni ye-HVLS kufutshane kakhulu kunohlobo lwegiya yesiqhelo. Ukuphakama kwefeni ikakhulu bubude bentonga yokwandisa. Ukuze sifumane isisombululo sokugubungela esisebenzayo, kwaye siqinisekise ukuba kukho indawo eyaneleyo yokhuseleko, sicebisa ukuba sikhethe intonga yokwandisa efanelekileyo, kwaye kufuneka siqwalasele indawo yokhuseleko phakathi kwencam yeblade kunye necrane (0.4m~-0.5m). Umzekelo, ukuba indawo ephakathi kwe-I-beam kwicrane yi-1.5m, sicebisa ukuba sikhethe intonga yokwandisa eyi-1m, ukuba kwenye imeko indawo phakathi kwe-I-beam kwicrane yi-3m, sicebisa ukuba sikhethe intonga yokwandisa eyi-2.25~2.5m. Ngoko ke iiblade zingasondela kumgangatho kwaye zifumane ukugubungela okukhulu.

Iingenelo Ezinamandla Zokudibanisa Iifeni zeHVLS NeeCranes

Ukoyisa umceli mngeni wokufakela kufanelekile umzamo. Iingenelo zinkulu kakhulu:

- Ukuphucula intuthuzelo kunye nokhuseleko lwabasebenzi:Ukuhambisa umoya omninzi kuthintela umoya oshushu ongashukumiyo ohlala uhleli eluphahleni (ukudilika) kwaye kudala umoya opholileyo kumgangatho womgangatho. Oku kunciphisa uxinzelelo olunxulumene nobushushu kwaye kuphucula isimilo kubasebenzi abasemgangathweni kwanabasebenzi beekhreyini.

- Imveliso Ephuculweyo:Abasebenzi abakhululekileyo ngabasebenzi abavelisayo nabagxile ngakumbi. Umoya ofanelekileyo unciphisa umsi kunye nokufuma.

- Ukonga Amandla Okubalulekileyo:Ngokutshabalalisa ubushushu ebusika, iifeni ze-HVLS zinokunciphisa iindleko zokufudumeza ukuya kuthi ga kwi-30%. Ehlotyeni, zivumela ukuba iindawo zokuseta i-thermostat zinyuswe, nto leyo enciphisa iindleko zomoya opholileyo.

- Ukukhuselwa kweeAsethi:Ukuhamba komoya rhoqo kunceda ukulawula ukufuma, kunciphisa umngcipheko wokugqwala kwizixhobo, oomatshini, kunye nekreyini ngokwayo.

Imibuzo ebuzwa rhoqo: Iifeni zeHVLS kunye neeKrayini

Q: Yeyiphi indawo encinci ekhuselekileyo phakathi kwe-fan blade kunye ne-crane?

A:Akukho mgangatho uqhelekileyo, kodwa ubuncinci beenyawo ezi-3-5 buhlala bucetyiswa njengesixhobo sokukhusela ukuqwalasela naluphi na utshintsho olunokwenzeka okanye ukungalingani kwezibalo.Ifeni ye-HVLSumenzi uza kubonelela ngemfuneko ethile.

Q: Ngaba ifeni efakwe kwi-crane ingaqhagamshelwa kumbane?

A:Ewe. Oku kudla ngokwenziwa kusetyenziswa isixhobo esilungiselelwe ngokukodwainkqubo yombane yekreyini, njengenkqubo yefestoon okanye ibha yomqhubi, enika amandla aqhubekayo njengoko ikreyini kunye nefeni zihamba.

Q: Ngubani omele aphathe ukufakelwa?

A:Soloko usebenzisa umfaki oqinisekisiweyo nonamava ogxile kwiifeni ze-HVLS kwizicelo zoshishino. Baza kusebenzisana neenjineli zezakhiwo kunye neqela lesakhiwo sakho ukuqinisekisa ukufakwa okukhuselekileyo nokuthobela ikhowudi.

Isiphelo

Ukudibanisa ifeni yeHVLS kumzi-mveliso onekreyini ephezu kwentloko akwanelanga nje kuphela ukuba yinto enokwenzeka kodwa inenzuzo enkulu. Ngokukhetha indlela echanekileyo yokufakela—ukufakwa kwesakhiwo ukuze kugqunywe ngokubanzi okanye ukufakwa kwekreyini ukuze kungene umoya ojoliswe kuwo—kwaye ulandela imigaqo engqongqo yokhuseleko kunye nobunjineli, ungavula amandla apheleleyo okuphucula ukuhamba komoya.

Isiphumo kukuba indawo yokusebenza ekhuselekileyo, ekhululekileyo, nesebenza kakuhle ehlawulela imveliso eyonyukileyo kunye neebhili zamandla ezincitshisiweyo.

Ixesha lokuthumela: Novemba-05-2025